- Characteristics and application of ultrasonic mask ear band spot welder[ 2020-09-16 ]

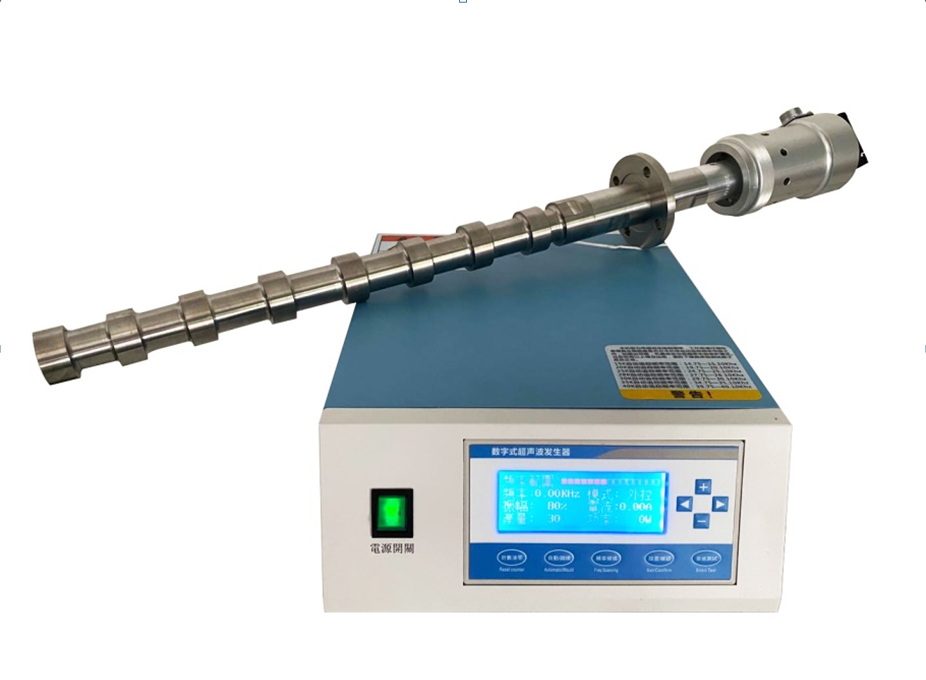

- The ultrasonic generator converts 50 / 60 Hz current to 20 kHz. The sensor converts it into mechanical motion of the same frequency again and transmits it to the welded joint through the amplitude modulator. The vibration energy received by the welded joint is transferred to the non-woven fabric mask joint to be welded, and the vibration energy is

- What is ultrasonic welding machine and where is it used?[ 2020-09-15 ]

- According to the level of automation, ultrasonic welding machine can be divided into automatic welding machine, semi-automatic ultrasonic welding machine and manual welding machine. For modern enterprises, the higher the automation level is, the more conducive to the production line of the enterprise. Therefore, the use of automatic welding machin

- Welding process of ultrasonic welding machine[ 2020-09-15 ]

- The ultrasonic welding machine transforms the current 50 / 60Hz electric frequency into 20kHz or 40KHz electric energy through a transistor function equipment, and supplies it to the ultrasonic converter. The converter converts the electrical energy into mechanical vibration energy for ultrasonic, and the voltage regulator is responsible for trans

- Difference between ultrasonic cutting and laser cutting[ 2020-09-15 ]

- Non woven fabric has the characteristics of soft, thin, sticky and easy to deform under stress. According to the design requirements, a laser cutting machine is purchased for cutting. However, in practical application, the edge of the cloth will always be scorched yellow (even black) and hard. After investigation, it is found that ultrasonic cutti

- What are the advantages of ultrasonic welding compared with ordinary welding?[ 2020-09-15 ]

- The connection between metals and the fusion of plastics and plastics. In order to make the connection more firm, the welding method will be selected. The welding used in the past is relatively simple, but this kind of simple welding can only weld some common metals, and the firmness is relatively poor. Now ultrasonic welding is more and more wide

- Tin plating and welding of ultrasonic soldering iron equipment[ 2020-09-14 ]

- Traditional tin plating equipment usually uses corrosive flux to remove oxide layer or impurity on the surface more or less. In addition, it is impossible to weld materials such as glass, ceramic and aluminum with traditional tin plating equipment. The new technology of ultrasonic driven welding joint does not need to add corrosive acid / flux. &

Contactus

Hotline:

+86-15088693503

WhatsApp:+86-15088693503

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400