Welding process of ultrasonic welding machine

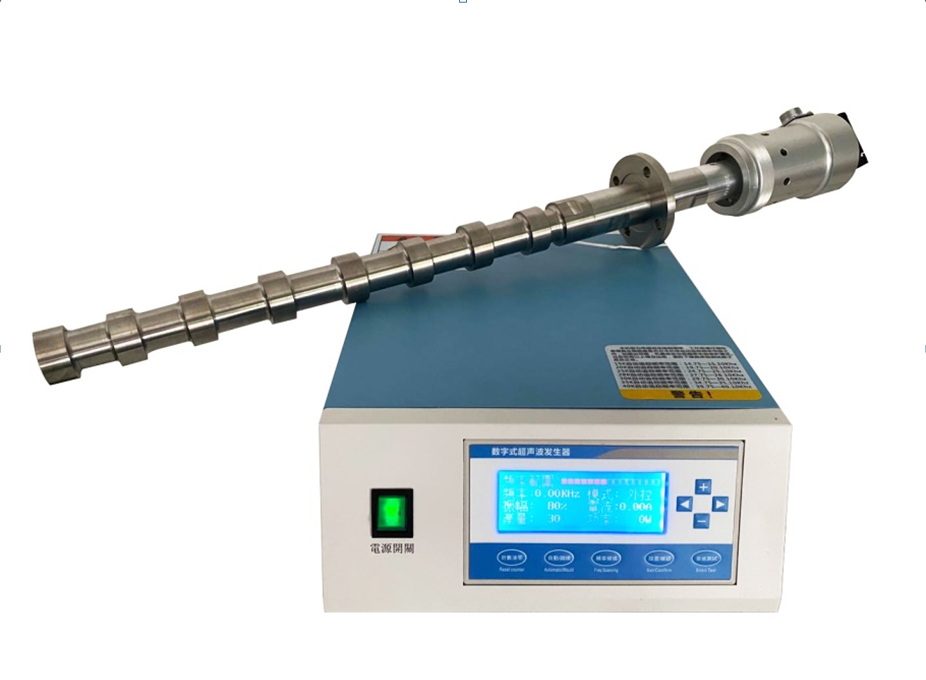

The ultrasonic welding machine transforms the current 50 / 60Hz electric frequency into 20kHz or 40KHz electric energy through a transistor function equipment, and supplies it to the ultrasonic converter. The converter converts the electrical energy into mechanical vibration energy for ultrasonic, and the voltage regulator is responsible for transmitting the converted mechanical energy to the welding head of the ultrasonic welding machine.

In the welding process of ultrasonic welding machine, one of the workpieces is fixed, and the other one is vibrated repeatedly on its surface at the frequency of 20 / 40KHz. At the same time, the pressure is applied to the workpiece to form a firm combination between the workpieces, so that the ultrasonic welding machine can achieve the welding effect.

Ultrasonic welding joint transmits mechanical vibration energy directly to the bonding surface through the welding work piece. Vibration friction generates heat energy to melt the plastic. The vibration stops when the molten material reaches the interface.

Holding pressure for a short time can make the melt form a strong molecular bond when it solidifies on the bonding surface. The whole cycle is usually completed in less than one second, but its welding strength is close to that of a connected material.

Contactus

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400