Difference between ultrasonic cutting and laser cutting

Non woven fabric has the characteristics of soft, thin, sticky and easy to deform under stress. According to the design requirements, a laser cutting machine is purchased for cutting. However, in practical application, the edge of the cloth will always be scorched yellow (even black) and hard. After investigation, it is found that ultrasonic cutting can avoid such situations. What is the difference between laser cutting and ultrasonic cutting?

1. Different principles

(1) Principle of ultrasonic cutting

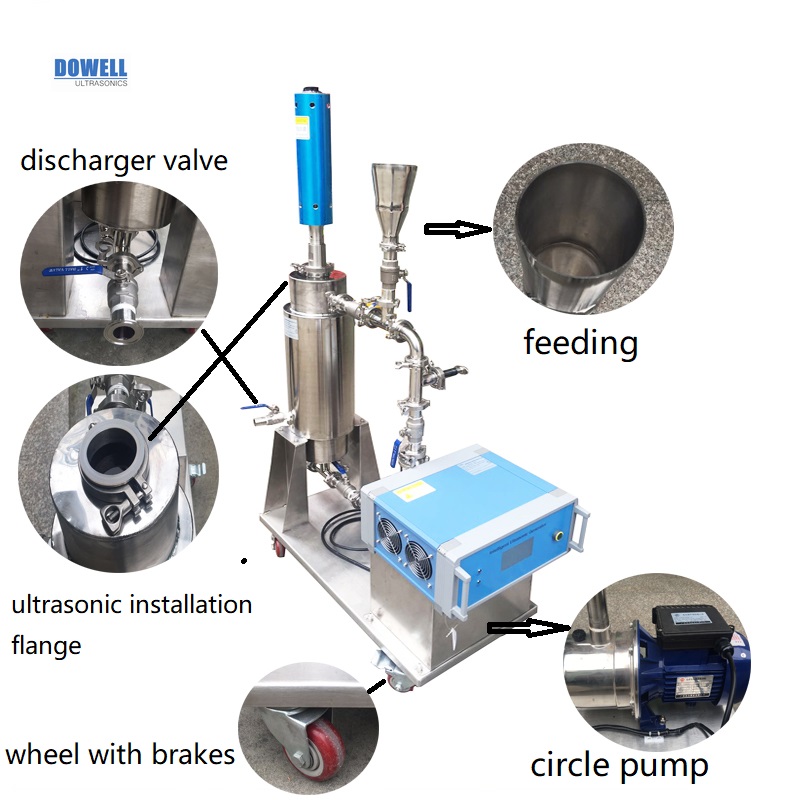

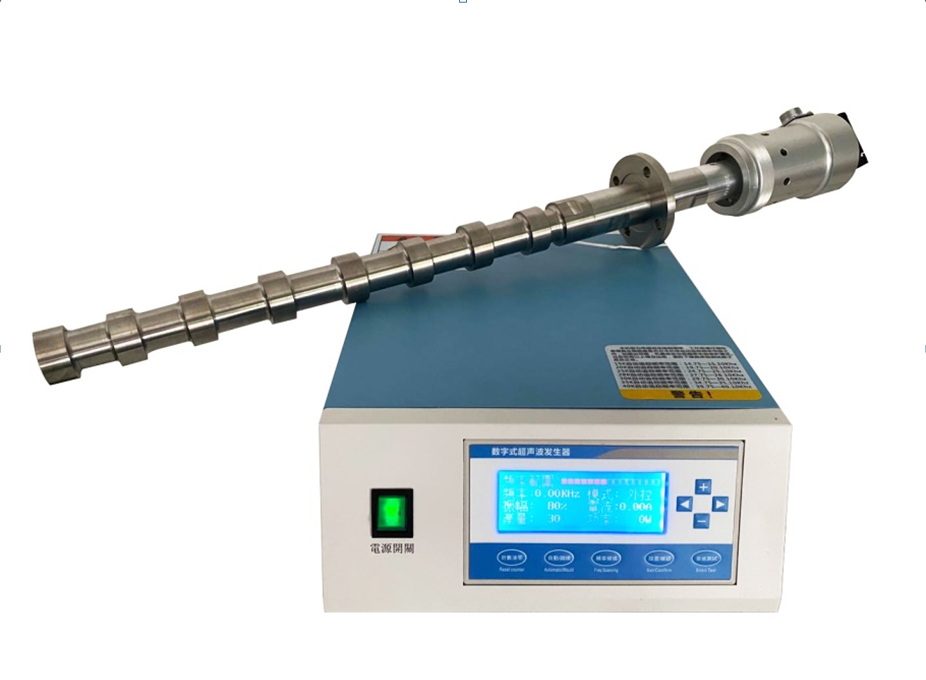

When cutting with ultrasonic technology, the front and rear vibration generated by the ultrasonic vibrator installed behind the main shaft is transmitted to the outer circle of the grinding wheel blade through the base platform of the main shaft and grinding wheel blade, and converted into the expansion movement in the radial direction. The ideal vibration direction required by ultrasonic machining can be obtained by this vibration conversion method.

(2) Principle of laser cutting

The principle of laser cutting is to use the focused high-power density laser beam to irradiate the workpiece, so that the irradiated material can melt, vaporize, ablate or reach the ignition point. At the same time, with the help of the high-speed airflow coaxial with the beam, the molten material is blown away, so as to realize the cutting of the workpiece. Laser cutting is one of the thermal cutting methods.

2. Different characteristics

(1) Characteristics of ultrasonic cutting

Ultrasonic cutting has the advantages of smooth and reliable incision, accurate cutting edge, no deformation, no edge warping, fuzzing, wire drawing and wrinkling. The avoidable "laser cutting machine" has the disadvantages of rough cutting edge, focal edge and pilling, but the automation of ultrasonic cutting machine is more difficult than that of laser cutting machine, so the efficiency of laser cutting is higher than that of ultrasonic cutting.

(2) Characteristics of laser cutting

As a new processing method, laser processing has been widely used in leather, textile and clothing industry for its advantages of accurate processing, fast processing, simple operation and high degree of automation. Compared with the traditional cutting method, laser cutting machine not only has low price and low consumption, but also has the advantages of safe operation and simple maintenance. It can work continuously for 24 hours because there is no mechanical pressure on the workpiece during laser processing. The non-woven fabric cut by laser machine has the advantages of no yellowing, automatic edge closing, no loose edge, no deformation, no hardening, uniform and accurate size; it can cut any complicated shape; it has high efficiency and low cost, and can cut lace of any shape and size with computer design graphics. High development speed: due to the combination of laser and computer technology, users can achieve laser engraving output as long as they design on the computer, and can change engraving at any time. They can design and produce products at the same time.

Contactus

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400