Composition and purchase precautions of ultrasonic welding machine

With the market demand for masks, the heat of ultrasonic welding system is still increasing. The system can be used in the welding of mask nose bar, welding after folding, breathing valve welding, multi-layer rolling welding and ear band welding.

Ultrasonic generator, ultrasonic welding machine, ultrasonic welding machine and welding equipment.

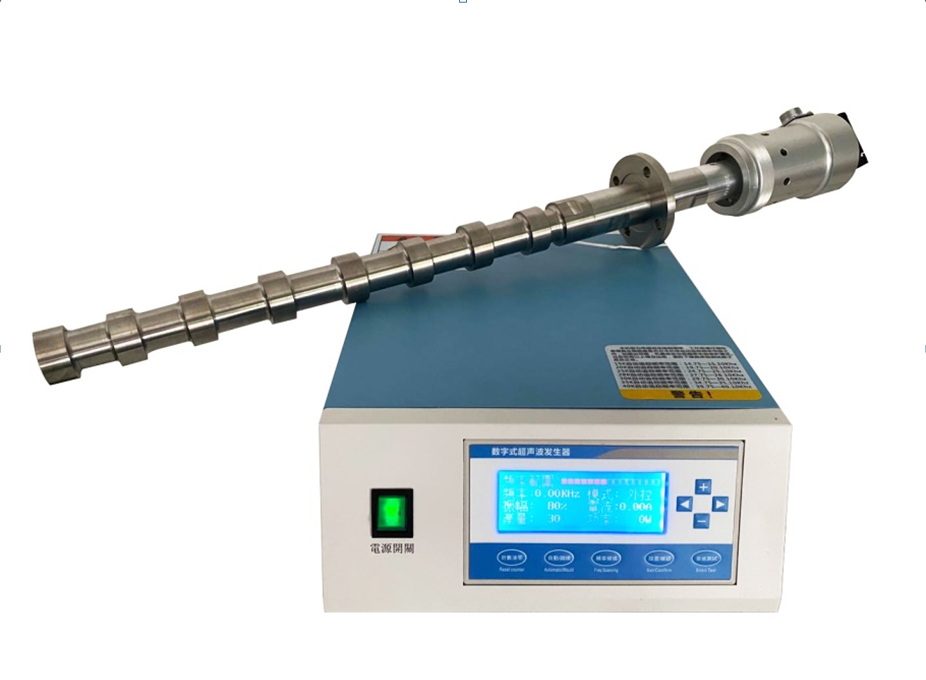

1. Ultrasonic transducer

The function of ultrasonic transducer is to change the power frequency (50 Hz or 60 Hz) voltage into ultrasonic frequency voltage. The microprocessor controls the welding cycle and feeds back the key welding information to the user through the user interface. The user interface also allows the operator to enter the required welding parameters.

The transducer transforms the ultrasonic frequency voltage from the generator into ultrasonic mechanical vibration with the same frequency through the inverse piezoelectric effect. When the sinusoidal signal is supplied to the transducer via the electrode, the piezoelectric sheet expands and contracts, resulting in an axial peak to peak motion of 15 ~ 20 μ M.

When purchasing, pay attention to consult the material of piezoelectric plate, he decides the durability and failure rate of transducer. Huayun ultrasonic transducer adopts electrostrictive energy exchange device and barium titanate ceramic plate. The piezoelectric effect is 20-30 times larger than that of quartz crystal in ordinary transducer.

Full digital system control can be selected to realize automatic frequency tracking, amplitude adjustment, amplitude compensation and constant power output, which can replace traditional manual welding and effectively improve production efficiency.

2. Ultrasonic horn

The horn has two functions. Its main function is to amplify the mechanical vibration produced by the transducer end and transmit the vibration to the welding head. The other function is to provide the position of the fixing kit on the welding press. When ultrasonic energy is applied to the transducer, the horn also expands and contracts. Like other parts in the welding kit, the horn is a tuning device, so it must also resonate at a specific frequency in order to transmit ultrasonic energy from the transducer to the welding head. In order to work effectively, the horn must be half wavelength or integral multiple of the ultrasonic wave in its manufacturing material. It is generally half wavelength.

3 ultrasonic welding head

Ultrasonic welding joint is the part of welding kit that provides energy to the parts to be welded. Like the ultrasonic horn, the welding head is also a tuning device and provides mechanical amplification in most applications, which ensures that there is enough amplitude at the end of the welding head to realize welding.

The design of parts and joints to be welded determines the size and style of welding head. The shape of the welding head is very important because the stress caused by the axial expansion and contraction of the welding head can cause cracking under high amplitude. When purchasing, attention should be paid to the structure and processing technology of the welding head, which affects the manufacturing accuracy of the welding head, and then affects the deviation of the system resonance. The welding head of Huayun ultrasonic welding system is processed with multiple axial slots, which is to ensure that the amplitude is located in the longitudinal direction.

Because the ultrasonic welding head works under high frequency vibration, a symmetrical design should be kept as far as possible to avoid the unbalanced stress and transverse vibration caused by the asymmetry of acoustic wave transmission. All processing equipment of Huayun ultrasonic welding joint adopts CNC equipment (such as machining center), so as to ensure the accuracy of processing meets the requirements.

The above describes the composition of ultrasonic welding system and procurement considerations, as a popular industry, we need to consult more than one company to ensure the selection of welding system suitable for their own use.

Contactus

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400